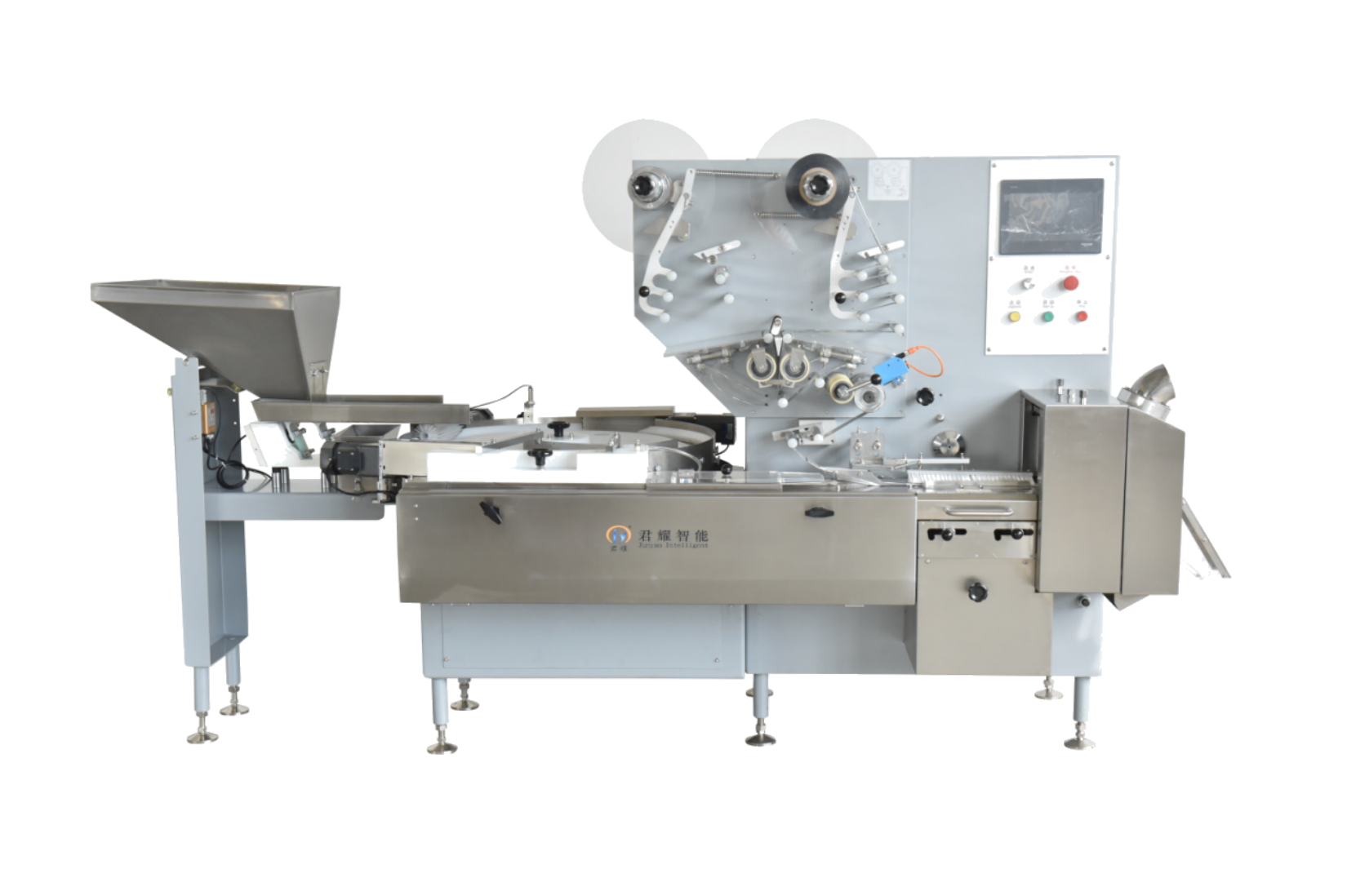

Introduction to High Speed Candy Pillow Packing Machine

--JY-ZB1500

The JY-ZB1500 high-speed fully automatic pillow packaging machine is suitable for the automatic arranging and packaging of solid, regularly shaped granular items, such as candies, chocolates, beef granules, preserved fruits, and similar products. It can achieve full automation from the output port of the forming equipment through docking conveyors, sorting, and packaging according to customer requirements. Furthermore, it can be customized in various ways to meet the output requirements of supporting forming equipment based on customer needs.

Performance Characteristics

1、Equipped with a triple-servo touch screen control system.

2、Features an oversized material arranging tray for effective sorting and low empty package rate.

3、Individual machine sections support independent operation, facilitating convenient maintenance and debugging.

4、Excels in high-speed stable operation, excellent sealing performance, and rapid packaging speed.

5、Bag length adjustment requires only touch screen settings—operates directly. Cutting position and feeding position can be modified anytime via the touch screen during operation stops.

6、Servo-driven transmission offers a simple structure and user-friendly operation.

7、304 stainless steel frame ensures food-grade safety compliance.

8、Dual-roll film system enables non-stop packaging film replacement.

Major Parameters of the Equipment

(1) Technical Parameters:

Voltage: 380V 50Hz

Total Power: 4.5KW

Weight: 1526KG

Dimensions: 3055×1437×1780mm

Compatible Products: Discs, spheres, squares, rectangles, ellipses, cylinders, etc.

Bag Length: 45-120mm

Max Speed: 50-1500 pcs/min

(2) Material Arranging Structure:

Oversized feeding tray ensures effective product alignment and minimizes empty packaging rate.

(3) Conveying Path Structure:

3.1 Food-contact surfaces made of 304 stainless steel.

3.2 Product position adjustment via touchscreen.

(4) Longitudinal Sealing Structure:

4.1 Tension-based sealing mechanism guarantees uniform package density and reliable high-speed sealing.

4.2 High-precision gear transmission ensures low-noise operation.

4.3 Heat-resistant bearings in sealing wheels extend service life.

4.4 Heating ring design optimizes thermal efficiency.

(5) Transverse Sealing Structure:

5.1 High-precision gears drive upper/lower sealing jaws for accuracy.

5.2 Heating tube system for transverse sealing.

(6) Film Feeding Structure:

6.1 Dual-roll system (Roll A/Roll B) with independent feed rollers.

6.2 Automatic film transfer between rolls at full speed without shutdown.

6.3 Film length adjustment:

- Automatic length calibration

- Manual setting per packaging requirements

(7) Drive Structure:

7.1 Servo-driven sealing jaws with precision reducer (auto-length adjustment).

7.2 Servo-controlled film feeding.

7.3 Servo-driven chain conveyor system.

(8) Control System:

8.1 Integrated servo controllers

8.2 High-efficiency servo motors

8.3 Touchscreen HMI

8.4 Low energy consumption

(9) Electrical Components:

Schneider Electric components ensure stable performance.

Copyright © Xing Junyao Intelligent Packaging Technology(Taizhou)Co.,Ltd - Privacy policy